Industrial solutions

This division handles mechanical machining on CNC milling and turning centers, based on the executive drawings provided by customers or our technical office. The production lines' machinery is state-of-the-art and constantly updated to ensure high-performance and competitive manufacturing. The entire process is monitored through our operational procedures, which ensure quality control and punctuality on all production runs. For more details, visit www.mgitaly.it

Weldings & Vacuum System

Vacuum technology is based on creating and maintaining a reduced-pressure environment, comparable (in some cases) to that of outer space. This is achieved through pumping systems capable of removing air—and therefore oxygen, nitrogen, humidity, particulate matter, and other substances—from a closed chamber. The result? A partial or near-absolute vacuum, in which the laws of physics behave significantly differently than in the atmospheric environment.

Laser, TIG, MIG/MAG, and a dedicated robot for high-quality welding services.

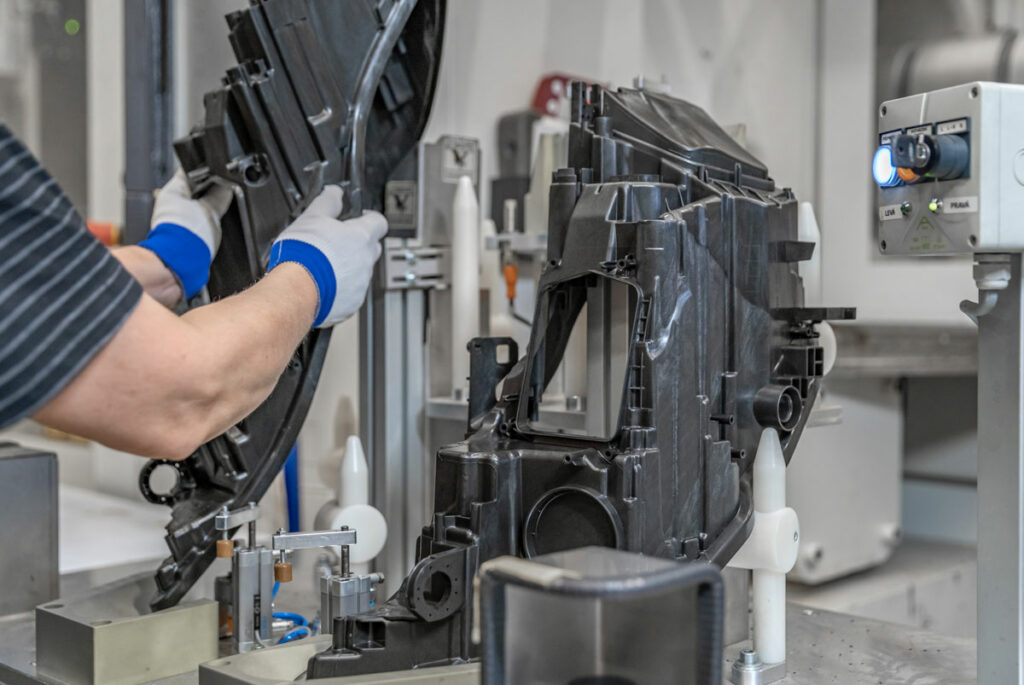

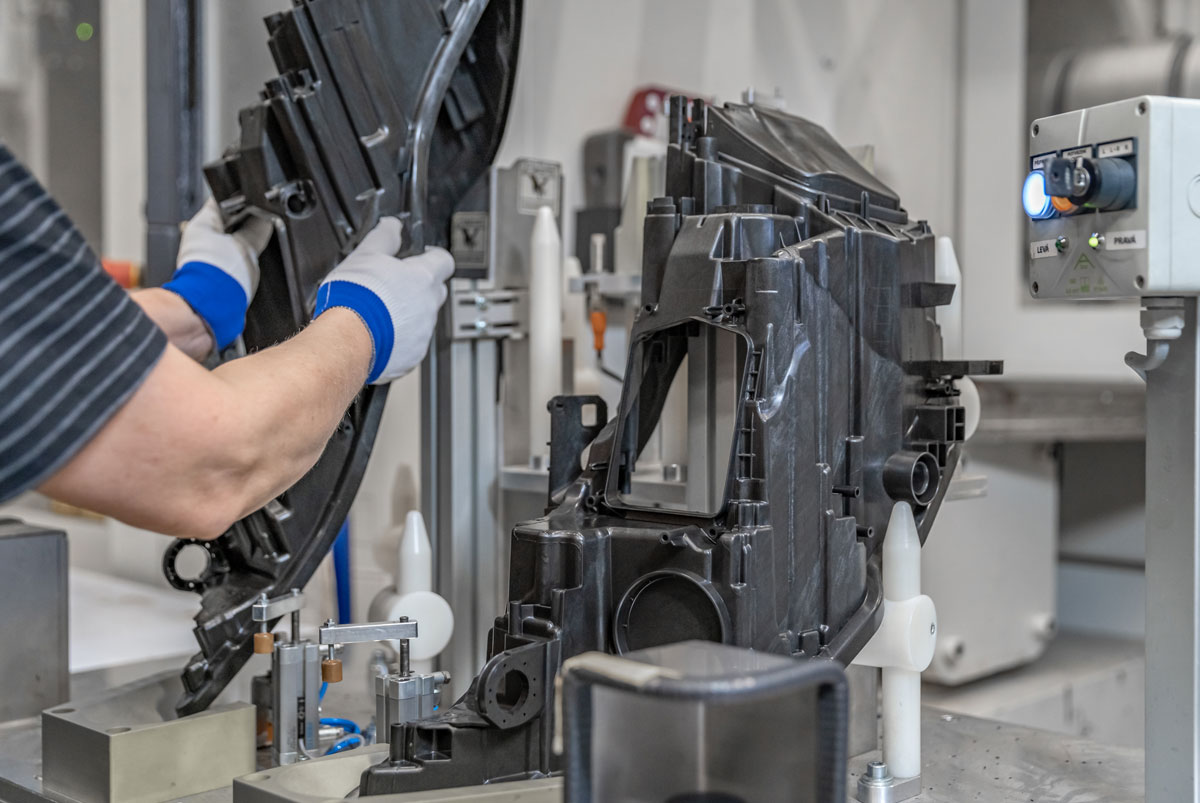

Plastic materials

Plastic materials for electrical insulation and mechanical components

Once operational, every system requires a powerful and reliable electrical system. Generators, transformers, and switchboards must always be coordinated with the expected performance and structure of the system. We assist you in construction with our thermoset semi-finished products, which have been used in the electrical industry worldwide for over 40 years. Highly resistant to electrical, mechanical, and thermal stress, our materials enable you to develop generators, transformers, and switchboards with high operational reliability.

Your advantages

High operational safety Long life Low flammability High electrical stability High mechanical stability High thermal resistance

Fields of application

Electrical systems High power systems Energy cooling systems, UPS, Systems with high operating temperatures.

Materials used:

Gpo3 – Pvc -Lexan – Vetronite

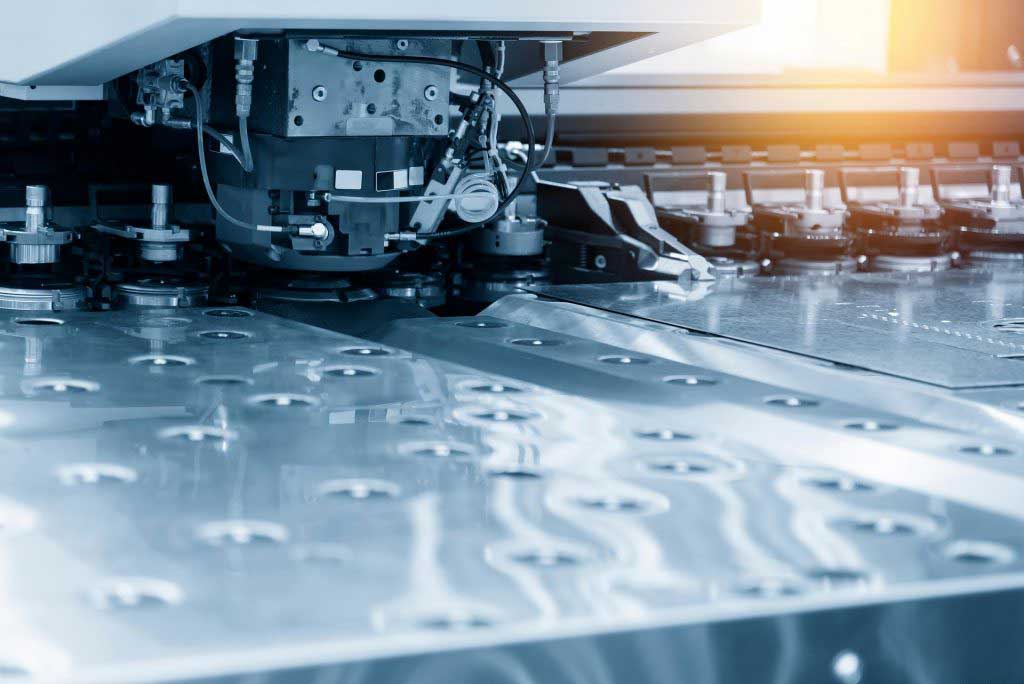

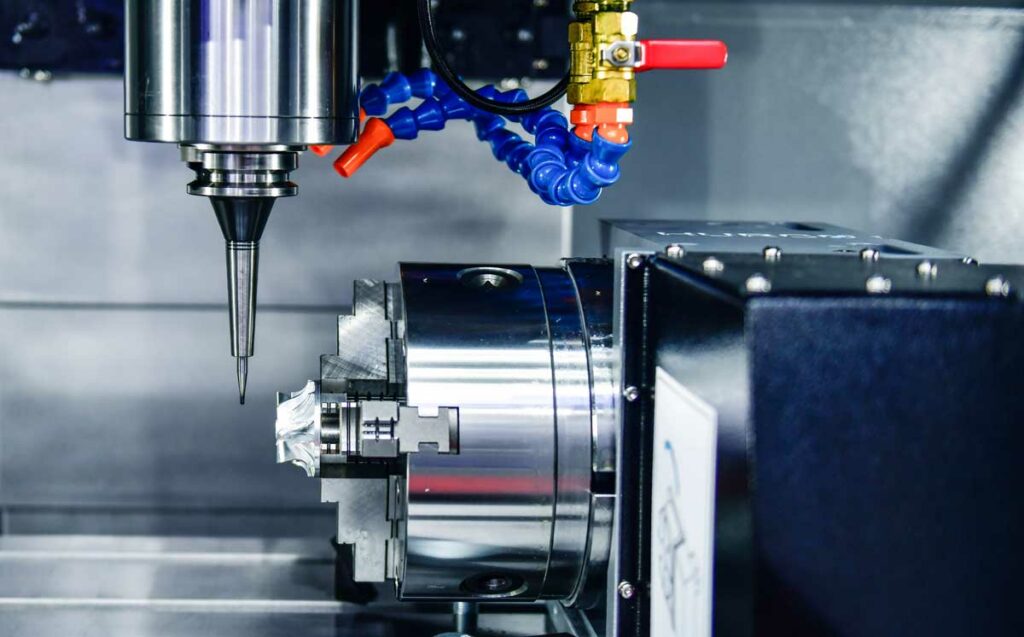

Milling

With a fleet of over 20 high-end machining centers, MG serves as a prime contractor for mechanical machining operations based on customer designs, ensuring the production of highly precise parts with reduced lead times and costs.

All CNC machines are always operated under the supervision of trained personnel who ensure the proper execution and dimensional control of the product they are producing.

To make this way of operating possible, department heads supervise the production cycle, while other qualified personnel perform some necessary and fundamental operations.

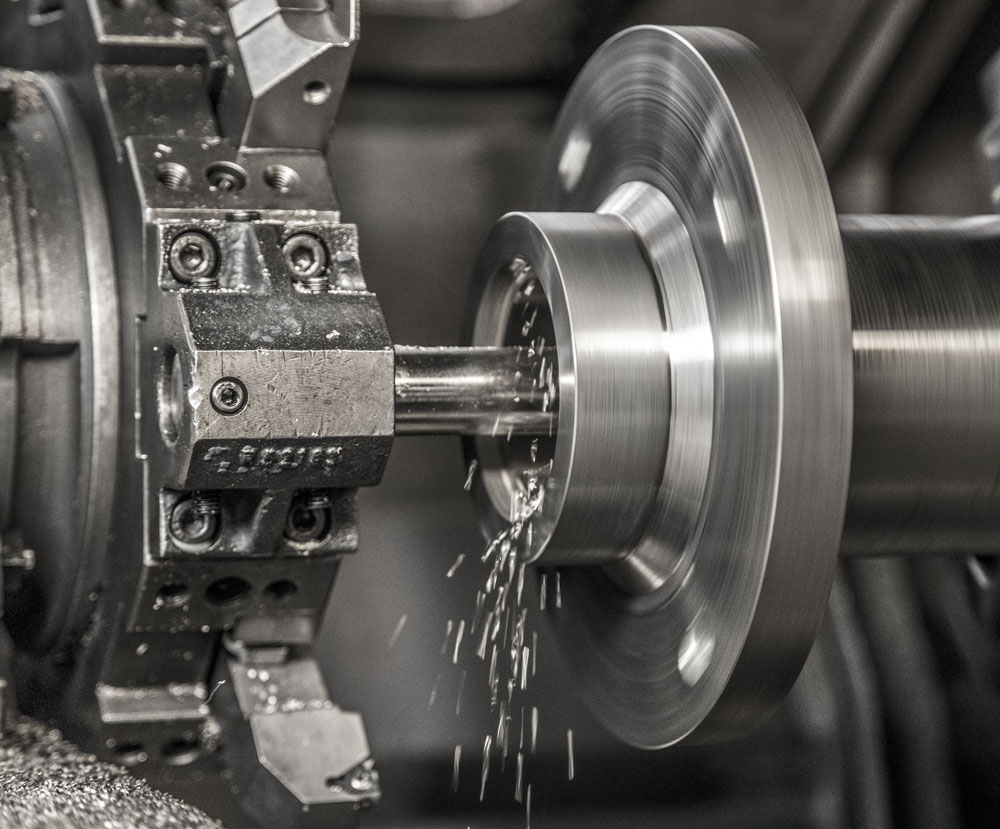

Turning

In the field of high-precision mechanical machining, M.G. also offers a numerically controlled turning service. We have state-of-the-art CNC turning machines. Thanks to computerized monitoring of the work phases, the company can guarantee constant, real-time monitoring of production progress and immediate traceability of completed or in-progress work.