Thermal management

TECHNOLOGY

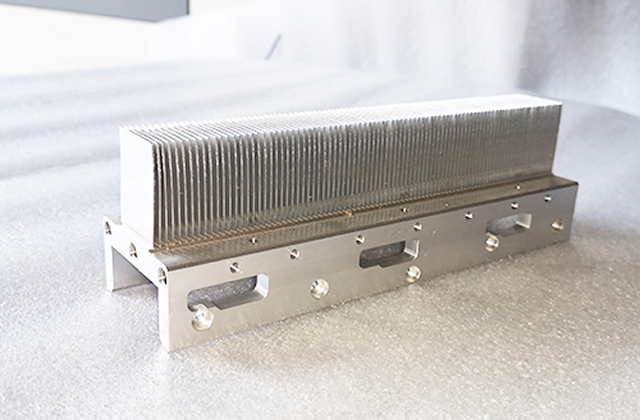

EXTRUDED

We are one of the world's leading manufacturers of aluminum heat sinks. Our main activities include the study, design, and development of profiles for the production of finished products.

Innovative and flexible, we can provide customized solutions for any type of application. We manufacture extruded and assembled heat sinks based on our customers' requests.

We have been developing new ideas for over 40 years, and our product range includes more than a thousand extruded aluminum profiles and more than 20,000 finished products.

VAPOR CHAMBER COOLING

MG ITALY vapor chambers offer an advanced solution for heat dissipation in high-performance applications. Thanks to the physical principle of phase change, heat is rapidly distributed across the entire surface, eliminating hot spots. Compact and customizable, they are ideal for high-density electronic devices or confined spaces. Made with quality materials and precision engineering, they ensure efficiency, reliability, and a long operating life.

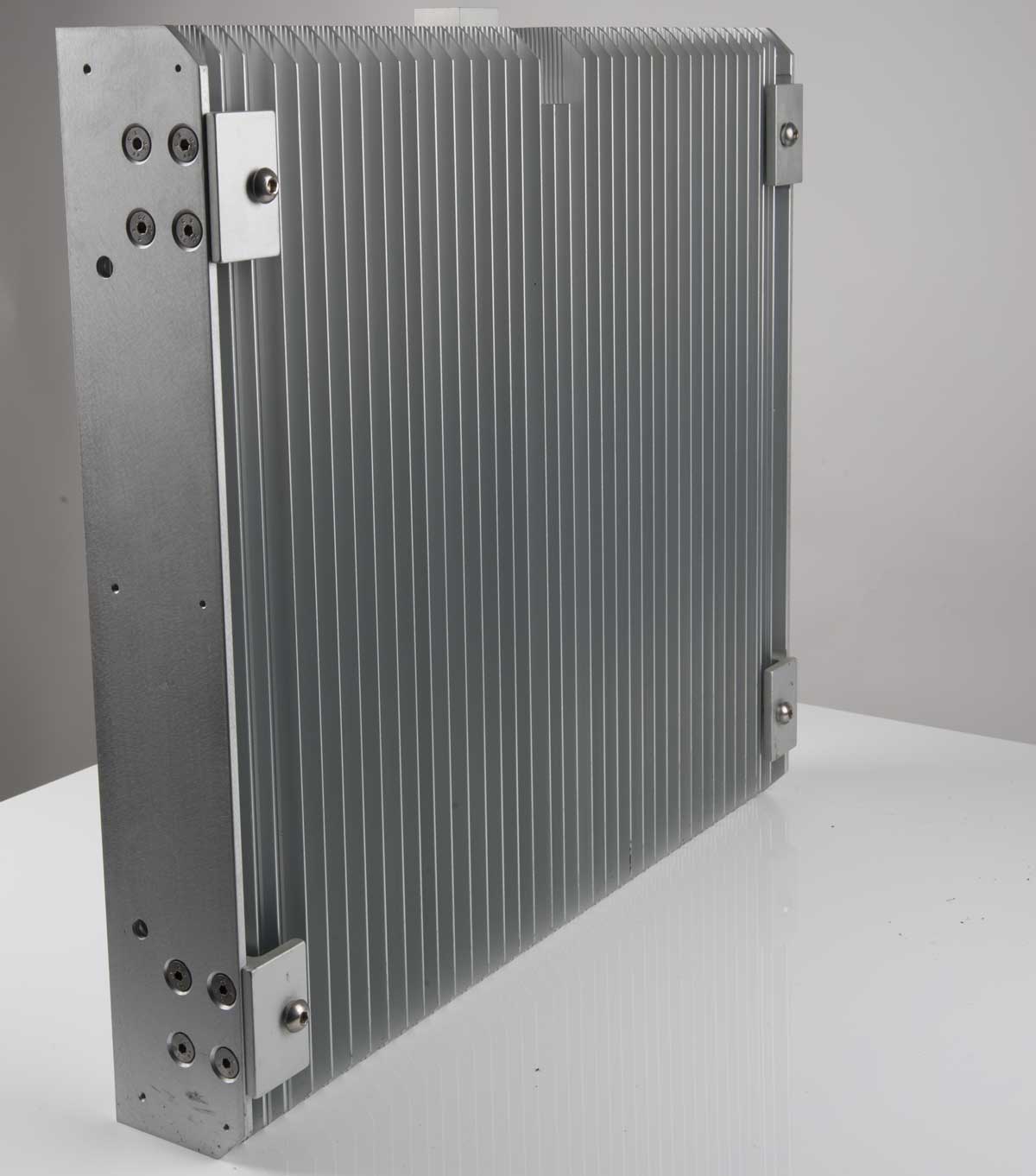

ASSEMBLED HEATSINKS

MG ITALY's PA series assembled heat sinks are designed for the most demanding applications in terms of power and heat dissipation. Each fin is mechanically inserted with precision, ensuring optimal thermal conduction and minimizing losses. The modular design allows for great flexibility in size and configuration, offering customized solutions for any need. Robust and durable, they are ideal for forced-cooling environments and critical operating conditions.

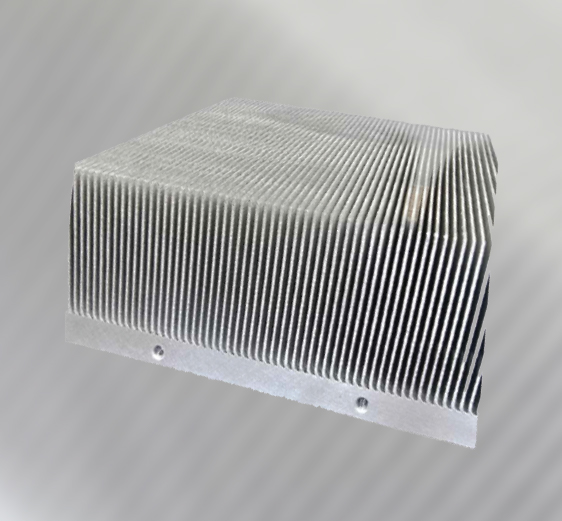

MG SKIVED

MG ITALY offers a line of finned heat sinks made with skived technology, in which the fins are obtained directly from a single block of metal, without welding or gluing. This

It guarantees exceptional thermal conduction and superior heat dissipation performance. Available in various sizes, geometries, and materials (aluminum or copper), they offer versatile and customizable solutions. Ideal for both passive and active cooling, they ensure reliability even in harsh environments.

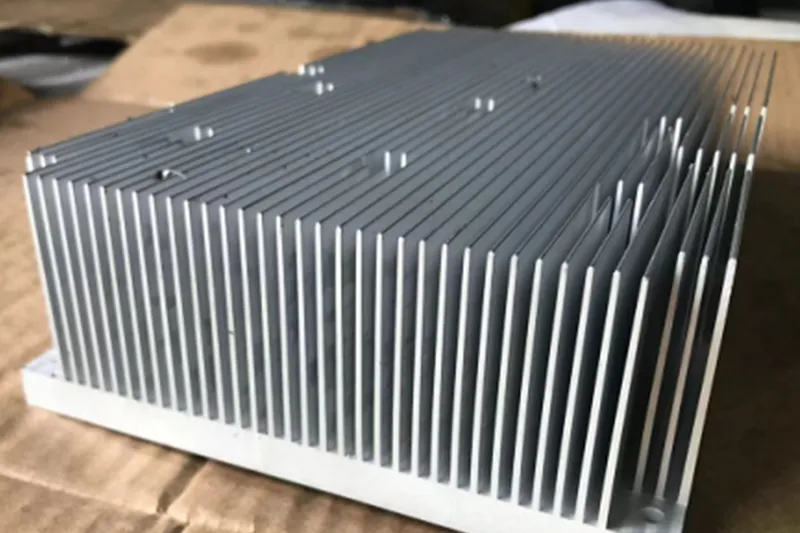

HEAT SINK PLUS

This technology allows us to offer completely custom heatsinks while respecting the features and performance of a standard solution.

This technology is achieved through the mechanical assembly of the base and fins using exclusive, proprietary technologies from MG iTALY. All this allows us to guarantee superior thermal performance and absolutely excellent mechanical characteristics. A totally innovative product line, completely custom heat sinks. It is created through the mechanical assembly of the base and fins using proprietary technology from MG iTALY. The mechanical characteristics are compatible with alloy 6000, with an aspect ratio of 96:1. From the raw material to the finished product: the thermal performance of our products is improved and unique compared to our competitors on the market today. We guarantee an average decrease in thermal resistance between 8% and 15%.

Novelty

Z-FIN PLUS: the new frontier of thermal dissipation

Conventional heatsinks quickly reach their limits. When heat builds, technology must evolve. MG iTALY has therefore developed a new range of high-tech heatsinks with excellent thermal performance.

Z-FIN PLUS is the latest addition to MG iTALY, featuring maximum efficiency, innovative design and high-performance alloy.

The new Z-FIN PLUS heatsink has been designed to maximize heat exchange with a revolutionary geometry. A distinctive feature of this technology are the new high-performance, interlocking knurled fins.

Added value

LIQUID COOLING

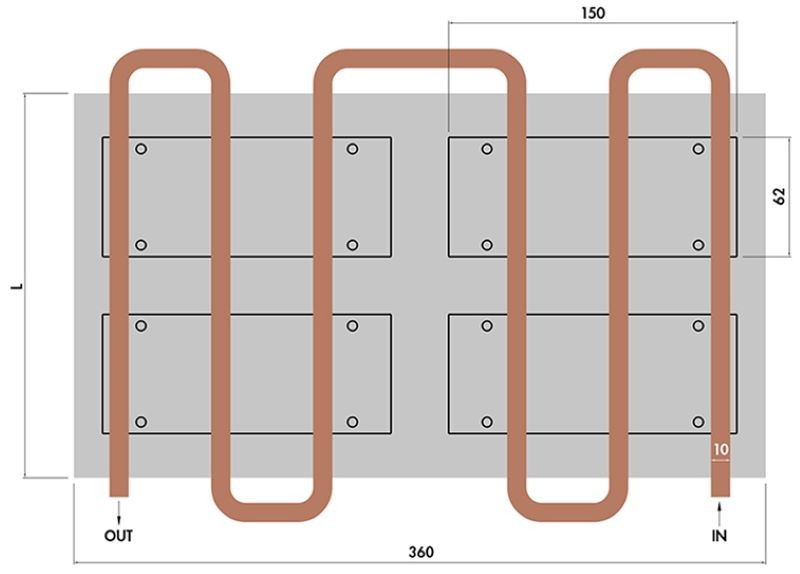

COLD PLATE

The COLD_PLATE solution is the optimal solution for efficiently managing complex systems with high concentrated power. Water cooling is thus becoming the ideal alternative for dissipating high power. This system avoids noise and vibration problems, considering that this dissipation system can also be used in dusty environments where forced air is not possible.

MG VORTICOLD

MG ITALY produces liquid-cooled cold plates with exclusive Turbulator technology, available in standard or custom versions. This innovative system improves cooling capacity by 30% compared to traditional plates, thanks to optimized liquid flow. The vacuum brazing process ensures high mechanical strength, even in harsh, acidic, or corrosive environments. The resulting joints are compatible with different metals, stable over time, and reliable.

MG UX COLD PLATE

MG ITALY leverages its expertise in vacuum brazing to produce high-performance cold plates with excellent thermal conduction and zero leakage. These components are designed for complex industrial applications where heat management is critical, such as power systems, precision lasers, medical, aerospace, and renewable energy. Each plate undergoes rigorous quality control, certifying its reliability even under extreme and continuous use. The combination of quality materials, advanced manufacturing processes, and Italian precision ensures reliability, durability, and superior performance over time.