CNC TORNIO

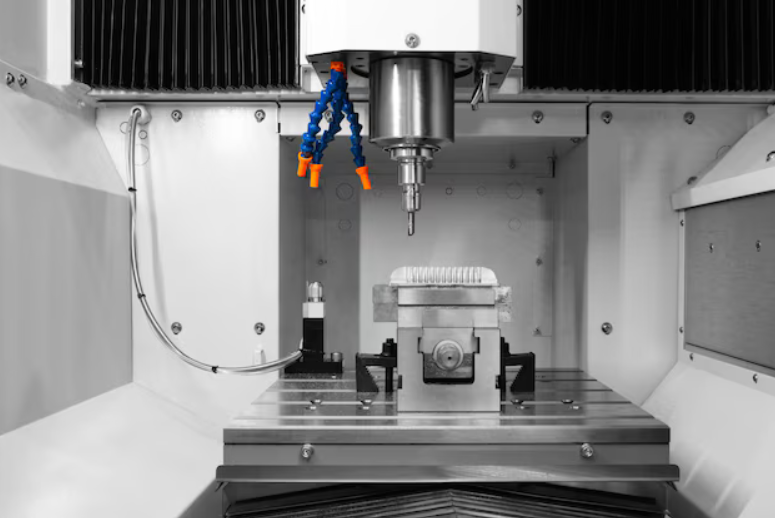

Precision engineering with CNC lathe technology refers to the processing of materials using computer numerical control (CNC) lathes, which allow for extremely high-precision turning operations.

In this process, the workpiece is rotated while a blade (tool) works on it to remove material, creating cylindrical, conical, or complex shapes.

CNC lathes are capable of producing parts with extremely tight tolerances, even on the order of a few microns, making them ideal for high-quality production and applications that require a high degree of precision, such as those in the aerospace, automotive, medical, and instrumentation industries.

The main advantage of this technology is its ability to produce parts with complex geometries, even in series, with consistent quality and end results. Furthermore, numerical control allows for automatic process management, minimizing human errors and optimizing processing times.

MG Italy has cutting-edge work tools such as Mazak machines for traditional and sliding head turning to meet every technical need.