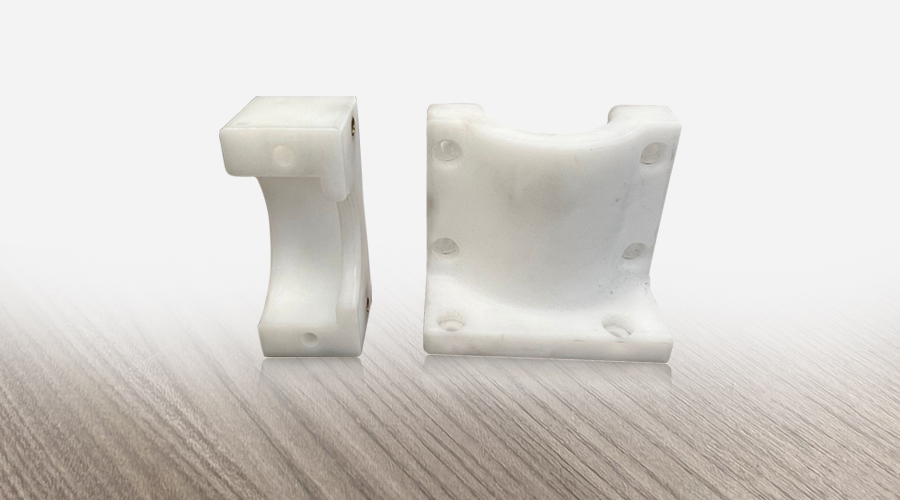

CNC PLASTIC

Precision mechanics with CNC (Computer Numerical Control) technology for plastics refers to the processing of plastic materials with numerically controlled machinery that allows for the production of high-precision components.

In this process, a computer controls the movement of the machine tool (milling machine, lathe, etc.) to perform operations such as cutting, milling, drilling, and polishing on plastic materials, such as engineering polymers, nylon, POM (acetal), PVC, and acrylic.

CNC technology offers numerous advantages:

High Precision

The machine is capable of performing operations with millimetric or even micrometric tolerances, ensuring consistent and repeatable quality in the components.

Reproducibility

Because the process is digitally controlled, it is possible to reproduce the same exact piece multiple times.

Flexibility

CNC programs can be easily modified to produce a variety of complex components.

Time optimization

Automatic processing allows for reduced production times and increased efficiency, especially for large quantities.

Specifically, when working with plastics, selecting the right machine and tools is essential to avoid deformation or damage to the material, which can be more susceptible to heat or pressure than metals. Using appropriate coolants, cutting speeds, and precise temperature control are crucial to achieving optimal results.