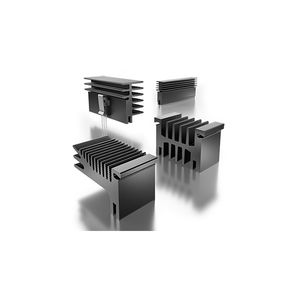

SPRING SYSTEM

Spring system for fixing heat sinks on TO-220, TO-247 and similar packages

The spring-loaded fastening system, in combination with heat sinks, is widely used in electronic PCB applications for effective cooling of packages such as TO-220, TO-247 and other similar formats.

Compared to traditional screw fastening, this system ensures the same performance in terms of heat dissipation, while offering significant technical and production advantages.

Among the main benefits:

Homogeneous pressure distribution

The spring exerts a centered and controlled force on the component, optimizing thermal contact between the device and the heatsink.

Ease of assembly

The spring exerts a centered and controlled force on the component, optimizing thermal contact between the device and the heatsink.

Reliability

the absence of mechanical tightening reduces the risk of damage to the components and increases their operating life.

Thanks to these characteristics, the spring system represents an ideal solution for improving the efficiency and practicality of cooling processes for electronic devices on boards.

Spring System for Fixing Heat Sinks on TO-220, TO-247 and Similar Packages

The spring-loaded fastening system is an advanced technical solution for installing heat sinks on semiconductor devices in TO-220, TO-247, and equivalent PCB-mounted packages. This method complements and provides a high-performance alternative to traditional mechanical fastening using screws and washers.

Main technical features:

Optimized thermal contact

The spring exerts a constant and evenly distributed pressure in the center of the component body, improving the thermal interface between the device and the heatsink.

Lack of tightening torque

Eliminates the risk of mechanical damage caused by incorrect tightening of screws, ensuring greater long-term reliability.

Ease of installation and maintenance

It allows for quick assembly and disassembly, ideal for automated processes or for field maintenance interventions.

Mechanical compatibility

Designed to integrate with standard aluminum heatsink profiles and PCB supports, the system can be adapted to different electronic layout configurations.

Operational Benefits

Reduction of assembly and rework times.

Controlled and repeatable pressure on the semiconductor package.

Better thermal management thanks to the maintenance of contact force over time.

Greater safety and mechanical strength than traditional fastening methods.

This technology is particularly suitable for industrial, automotive, power conversion and high-reliability systems applications where thermal performance and process repeatability are critical.