dissipazione

Con l’incremento della potenza dissipata dai dispositivi elettronici e la loro riduzione nelle dimensioni, la gestione della dissipazione di calore diventa un fattore sempre più importante nella progettazione dei prodotti elettronici.

Una temperatura di funzionamento troppo elevata ne diminuisce infatti drasticamente sia l’affidabilità che la vita media. La nostra società è specializzata nella progettazione e produzione di una gamma completa ed in continua evoluzione di dissipatori di ultima generazione per l’industria elettronica.

TECNOLOGIA ESTRUSI

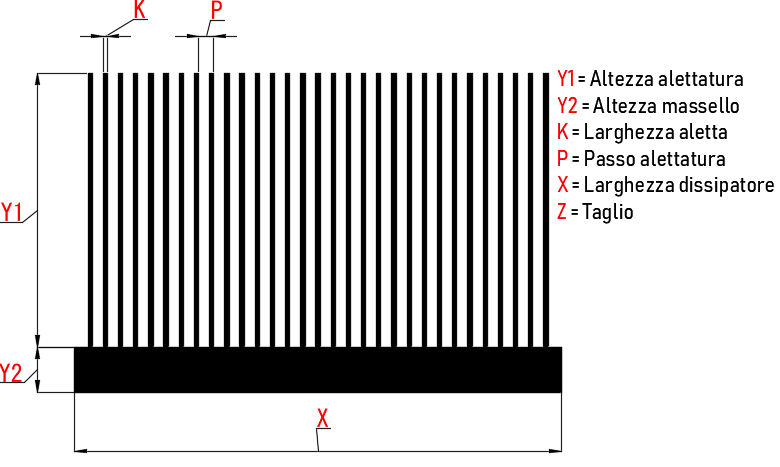

Il processo di estrusione dell’alluminio permette di ottenere profili di infinite forme anche complesse. Variando la forma del profilo, cambiando la superficie di contatto con l’aria e, di conseguenza, la capacità di dissipazione. I prodotti estrusi sono generalmente utilizzati in sistemi di media potenza sia in convezione naturale che forzata. I dissipatori estrusi vengono presentati suddivisi per forma (T, H, L, K, E, U, P), larghezza ed altezza, ed organizzati in ordine crescente di dimensioni. MG segue lavorazioni meccaniche seguendo le richieste del Cliente, garantendo affidabilità e qualità al prodotto finito.

TECNOLOGIA SALDATI

Per ottenere profili di dimensioni elevate, non realizzabili direttamente con l’estrusione, si possono saldare tra loro due o più profili estrusi. La saldatura è estremamente flessibile alle esigenze dimensionali del cliente e utilizzabile per qualsiasi modifica a profili già esistenti. MG Italy mette a disposizione la propria esperienza e disponibilità ai propri Clienti al fine di realizzare il prodotto richiesto. Mettiamo a disposizione appositi profili estrusi già smussati per una più semplice ed efficiente operazione di saldatura MIG e TIG. Tale tecnica ci permette di arrivare a realizzare profili con una larghezza massima di 900 mm.

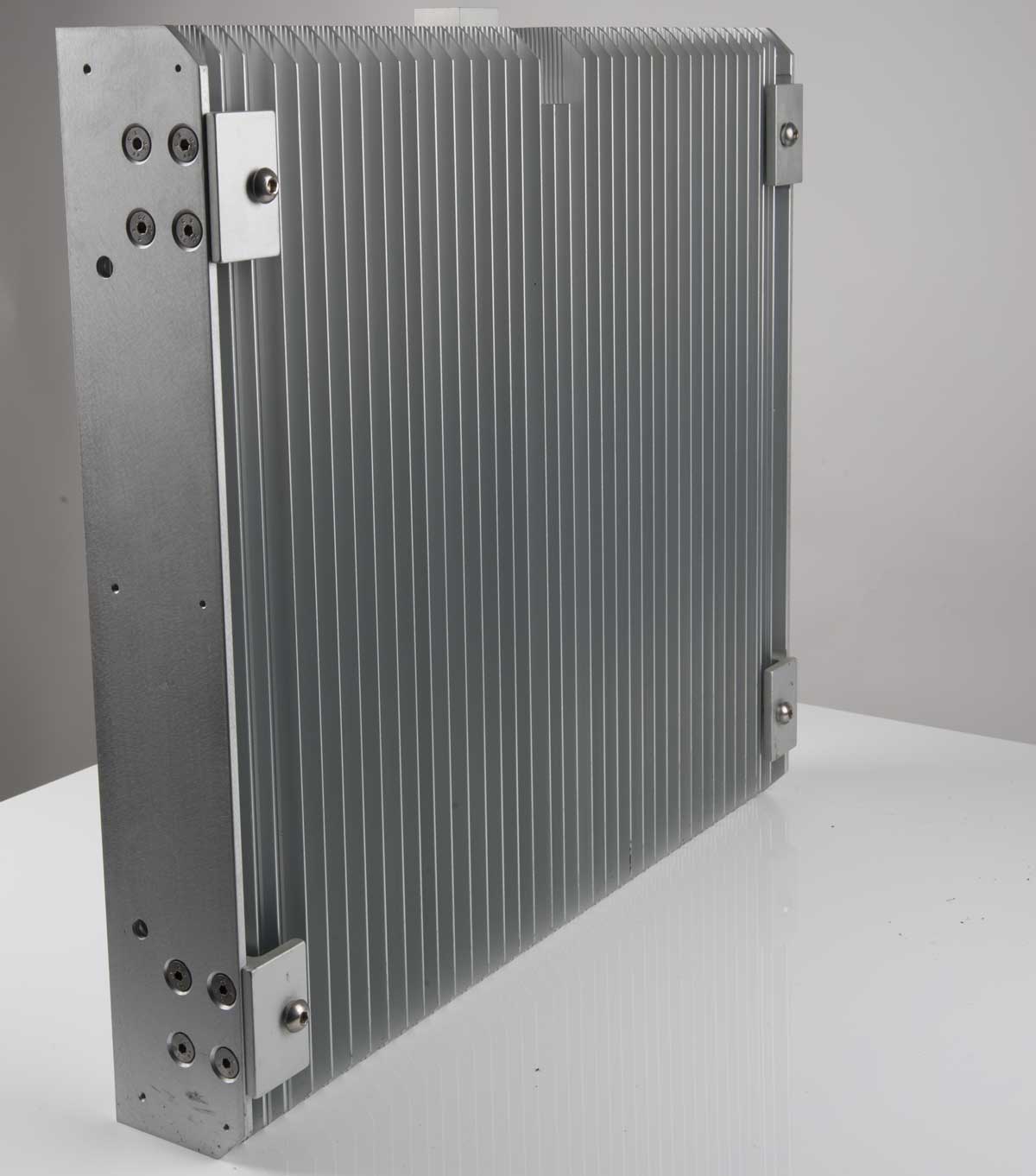

TECNOLOGIA ASSEMBLATI

Questa linea di prodotti nasce dalla continua e crescente esigenza di fornire dissipatori dalle prestazioni termiche sempre maggiori. Per raggiungere questo obiettivo abbiamo lavorato sulla sezione della singola aletta, sul numero di alette e sulla loro disposizione. Ottenuti assemblando meccanicamente le singole alette, i dissipatori ad alta efficienza offrono inoltre una elevata flessibilità dimensionale e le stesse caratteristiche meccaniche dei dissipatori estrusi, rendendoli particolarmente adatti per l’utilizzo in sistemi ad alta potenza in convezione forzata. Definiti Profili Assemblati (PA) sono suddivisi per larghezza ed altezza del singolo profilo aletta o modulo ed organizzati in ordine crescente di dimensioni.

TECNOLOGIA MGSKIVED

La tecnologia MGSKIVED viene utilizzata quando le alette hanno un’intensità che non può essere ottenuta con la tecnologia di estrusione. Con tale tecnologia possiamo realizzare dissipatori in rame o alluminio. Oggi, tale tecnologia ci permette di superare i limiti del rapporto di spessore e lunghezza dei dissipatori di calore convenzionali e le nostre macchine possono produrre dissipatori di calore ad alta densità e ad altissima efficienza. Le alette possono essere alte ed estremamente sottili e una struttura del dissipatore di calore extra lunga possono essere prodotti dalle nostre macchine smussanti dedicate utilizzando una tecnologia di taglio ad alta precisione di smussatura. Le nostre macchine utilizzano un unico blocco di materiale come rame o alluminio. Le alette e la base è “un pezzo unico”. Pertanto l’efficienza del dissipatore di calore con alette sfilate è fino a due volte superiore rispetto al dissipatore di calore tradizionale. L’efficienza della conduttività termica può raggiungere il 100% del materiale del profilo. Tale tecnologia può essere applicata nell’industria fotovoltaica, veicoli elettrici, inverter, prodotti di comunicazione, luci a led.